- English

- 中文

Products Overview

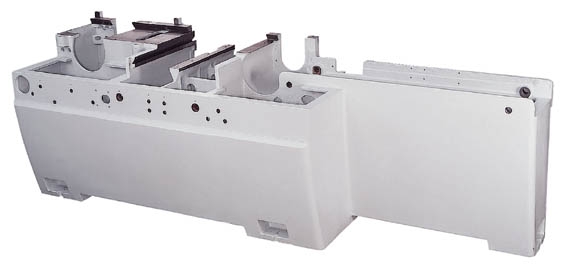

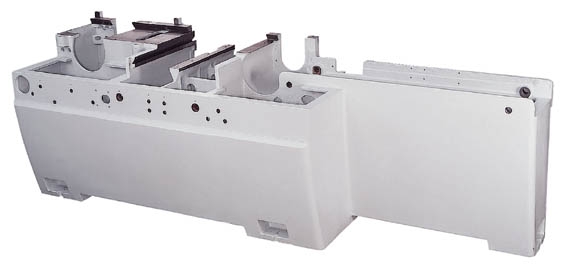

PIONEER-Series

The All-new Design of Pioneer-series 4-side Moulder

The Pioneer-series four sided moulder incorporates many outstanding features including high speed operation and superior accuracy. The Pioneer-series four sided moulder combines high efficiency with heavy duty operation and comes with a sound reputation for maximum dependability. The Pioneer-series four sided moulder is designed and engineer with the lastest in design manufacturung techniques to achieve a new era in four sided moulders.

PIONEER SERIES

Specification

|

|

Standard |

Optional |

|||

|

Capacity |

Working width |

18-230 mm |

240 mm |

250 mm |

260 mm |

|

Working thickness |

6-160 mm |

230 mm |

|

|

|

|

Min. working length |

200 mm |

|

|

|

|

|

Feed speed |

7-28 m/min |

7-36 m/min |

6-40 m/min |

6-60 m/min |

|

|

Number of spindles, min-max |

4-6 |

Universal / SAW or more… |

|||

|

Motor |

First bottom horizontal spindle |

7.5 HP |

10 HP |

15 HP |

|

|

Right vertical spindle |

7.5 HP |

10 HP |

15 HP |

|

|

|

Left vertical spindle |

10 HP |

15 HP |

20 HP |

25 HP |

|

|

Top horizontal spindle |

10 HP |

15 HP |

20 HP |

25 HP |

|

|

Bottom horizontal spindle |

10 HP |

15 HP |

20 HP |

25 HP |

|

|

Feed |

5 HP |

10 HP |

15 HP |

(Inverter) |

|

|

Elevation |

3/4 HP |

1 HP |

2 HP |

|

|

|

Cutting circles |

First bottom horizontal spindle |

100-160 mm |

|

|

|

|

Right vertical spindle |

110-200 mm |

|

|

|

|

|

Left vertical spindle |

110-200 mm |

|

|

|

|

|

Top horizontal spindle |

110-200 mm |

|

|

|

|

|

Bottom horizontal spindle |

110-180 mm |

110-250 mm |

Sawing Device (Simple) |

||

|

Spindle |

Spindle Diameter |

40 mm |

50 mm |

|

|

|

Spindle cutting speed |

6200 RPM |

8000 RPM |

9000 RPM |

|

|

|

Adjustment range of vertical spindle |

45 mm |

|

|

|

|

|

Adjustment range of horizontal spindle |

35 mm |

|

|

|

|

|

All other |

Dust outlet diameter |

140 mm |

160 mm |

|

|

|

Infeed table |

2 M |

1.2 M |

2.5 M |

3 M |

|

|

Feed roller diameter |

140 mm |

|

|

|

|

|

Pneumatic pressure for feed rollers, max |

6 bar (87psi) |

|

|

|

|

|

Adjustment range for infeed table |

10 mm |

|

|

|

|

** Specifications may be changed or modified without notice.

Standard

Optional

Spindle speed increase to 8000 rpm or 9000 rpm. Robust cast iron base.

Outboard bearing. Hydro lock cutter heads.

Infeed fence with roller & single direction transfer roller. Profile jointing (hydraulic with pneumatic)

Upper spindle straight jointing (hydraulic with pneumatic) CNC control with color panel (SIEMENS)

Universal spindle. Groove guide table.

Air cushion table. Saw mechanism.

Digital position controller. Pneumatic chipbreakers on top heads.

Pneumaric loading to side pressures. Central Lubrication with manual pump.